Australia offers up a wide range of challenging climatic and environmental conditions that makes safety and complying with Australian Standards very difficult. Almost half of Australia’s coastline is rated as prone to tropical cyclones (region C) and severe tropical cyclones (region D).

These regions are usually found in remote areas that are not serviced by mains water and electricity.

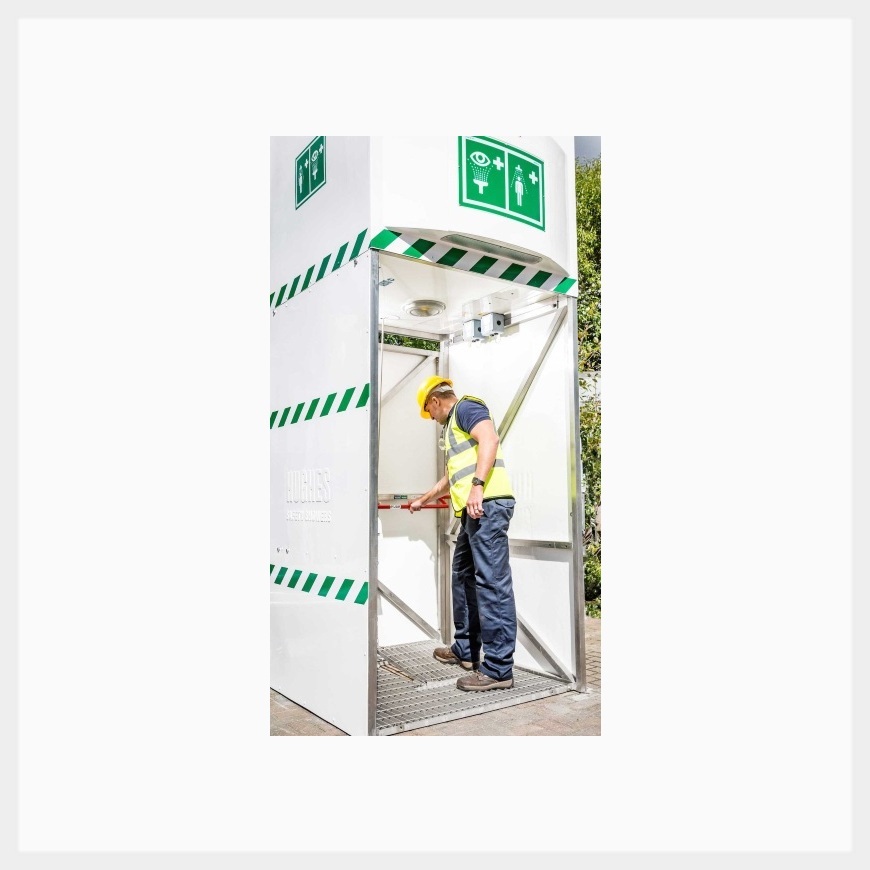

The Wind Region D Emergency Tank Shower and Eyewash has been developed by Spill Station to meet the needs of Australian industry in the most hostile of environments.

It is a gravity fed from a fully insulated tank so no pumps or power is required to run the shower/eyewash making it suitable for Zone I &II areas.

The frame is made from re-enforced stainless steel with tie down points located on each corner.

| Weight | 390 kg |

|---|---|

| Dimensions | 1420 × 1495 × 3746 mm |

| Features | Low pressure shower rose delivers large quantities of water in an even pattern that is non-injurious to the user. Thermal insulation assists in maintaining the water temperature in the tank to international standards in all climates. Instant activation by panic bar or optional foot panel Optional eye/face wash can be mounted internally or externally. Optional Zero Power Cooler units available for hot climates. Location: Indoor, Outdoor Climate: Hot (risk of over-heating), Cold (risk of freezing), Variable Installation: Free Standing / Floor Mounted Features: Eye/Face Wash Framework: Stainless Steel Capacity (Litres): 1500 |

| Inlet Connection Size & Type | 3/4” BSP Female |

| Shower Operation | Panic bar (optional foot panel control) |

| Eye/face Wash Operation | Lift lid up (optional foot treadle control) |

| Supply Pressure | 0.5 to 10 BAR G (7 to 145 PSI) |

| Flow at Operating Pressure | Shower – 76 litres/minute Eye/Face wash – 12 litres/minute |

| Electrical Equipment – Non-hazardous | Suitable for use in areas classified as non-hazardous |

| Electrical Equipment – Hazardous | ATEX Zone 1 & 2. Gas groups IIA & IIB. Temp Class T3 (IIC available) |

| Materials of Construction | Shower Rose: GRP stainless steel Piping & Valve Materials: uPVC and stainless steel Control Valve – Shower: uPVC 11/2” BSP ball valve Control Valve – Eye/face Wash: 1/2” 316L stainless steel full flow ball valve with stainless steel ball Eye/face Wash Strainer: 1/2” stainless steel Overflow: 1” BSP uPVC Ballcock Valve: 2 x 1/2” BSP brass Water Tank: 1500 litre (396 US Gallons) capacity heavy density polyethylene HDPE Tank Surround and Lid: Heavy-duty GRP in white (green or yellow available) Shower Frame and Legs: Stainless steel. Polished brush finish (paint options available) Pull Rods for Valve Activation: Stainless steel Foot Control Options: Panel foot control – Stainless steel/Treadle foot control – powder coated stainless steel All Fasteners and Fixings: Stainless steel |

| Minimum Ambient Operating Temperature | 16º C (60º F) (For 0º C (32º F) |

| Maximum Ambient Operating Temperature | 40º C (104º F) (+55º C (131º F) with cooling unit fitted) |